Non-destructive testing technology at the highest level.

Innovative solutions for quality assurance, material testing, and process monitoring.

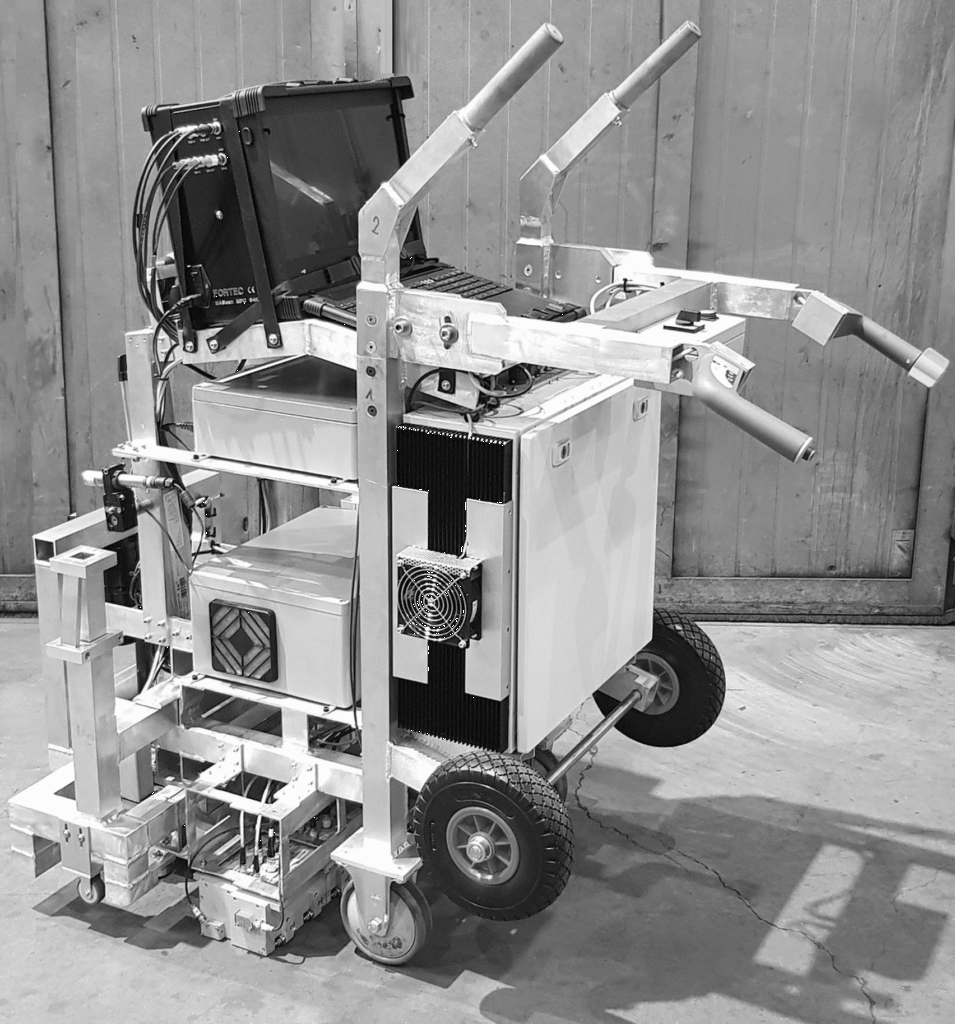

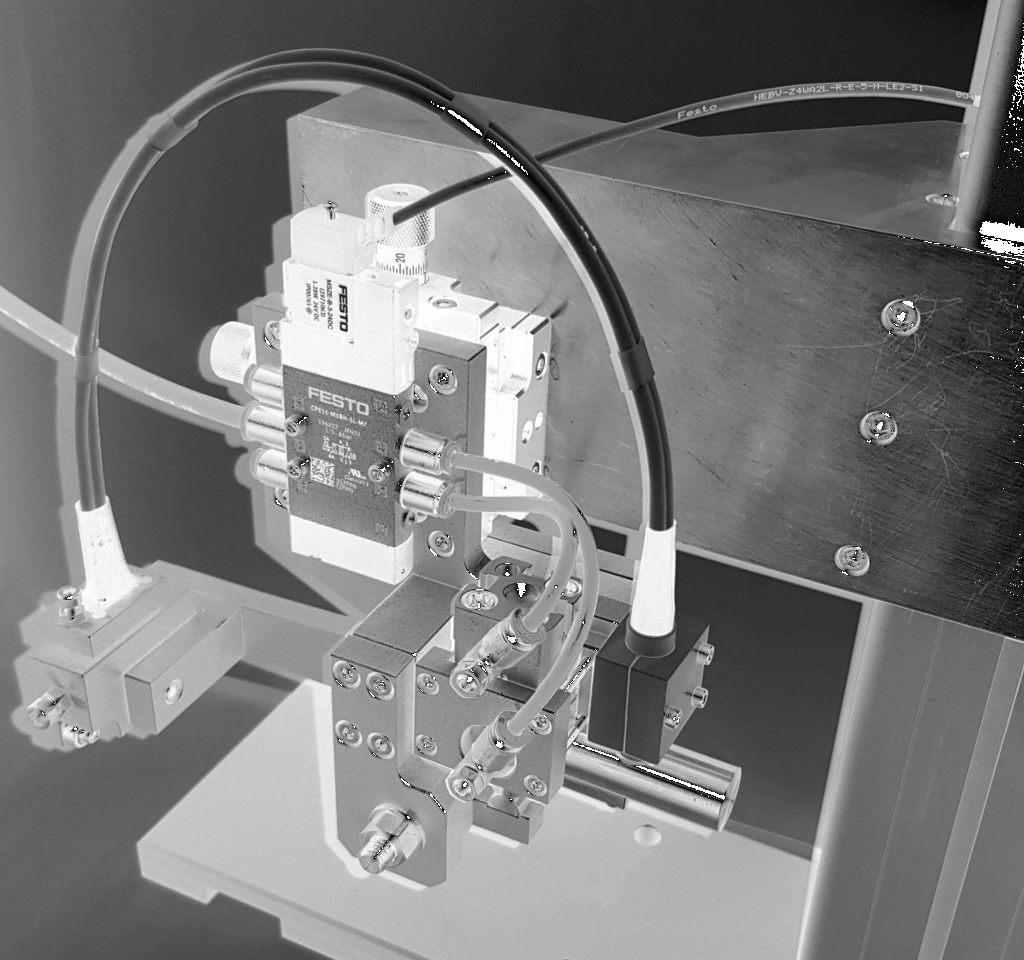

Fortec Forschungstechnik GmbH is your reliable partner for modern non-destructive testing (NDT) methods. With many years of experience in research, development, and application, we offer tailor-made solutions for defect detection, material characterization, and process monitoring — always at the cutting edge of technology.

Our range of services covers everything from the development of customized testing procedures and their technical implementation to integration and commissioning in industrial production processes. Throughout, quality, precision, and cost efficiency are always our top priorities.

Our services – your advantage.

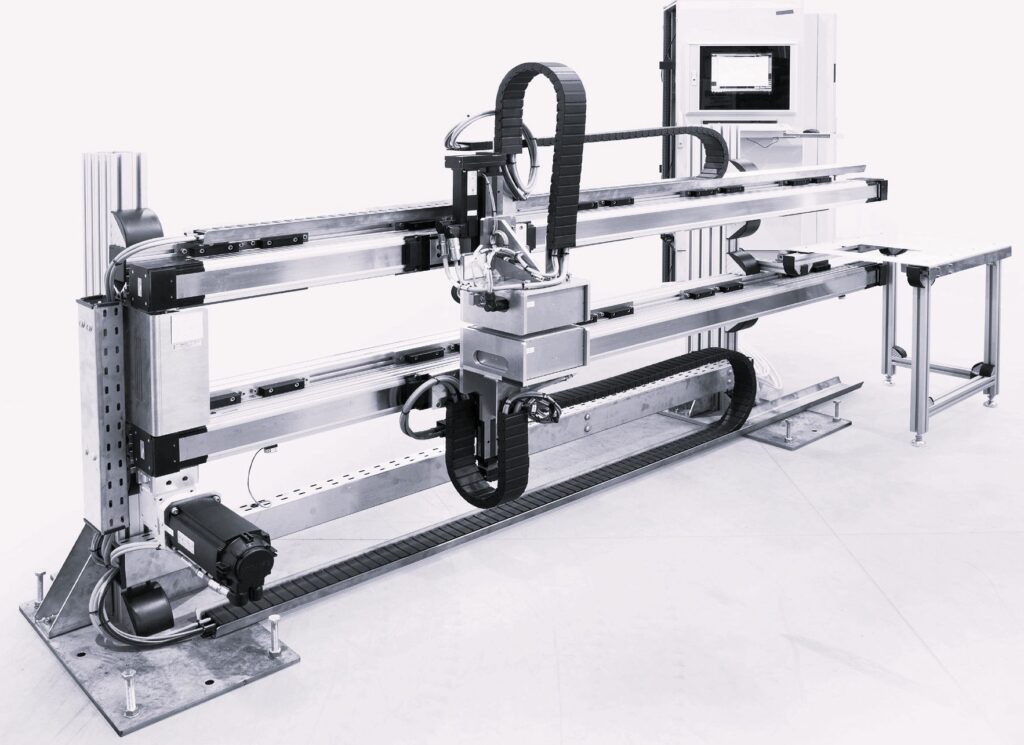

Our product solutions at a glance

Efficient testing technologies for non-destructive defect detection, material characterization, and process monitoring.

Precise, reliable, and industry-ready.